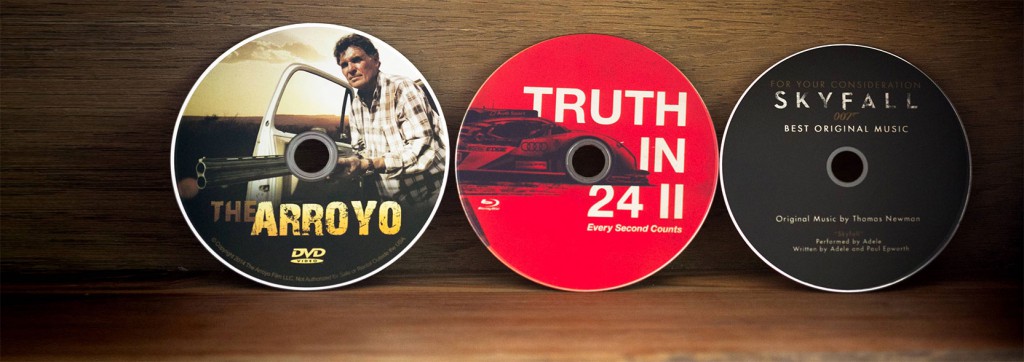

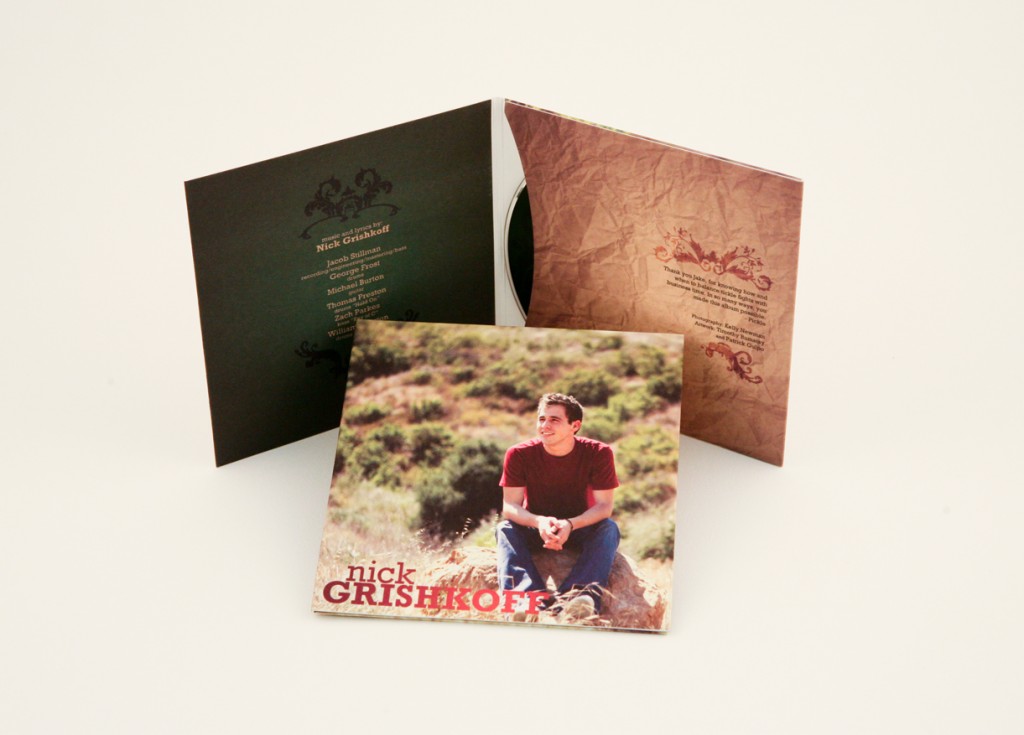

When CD, DVD, or Blurays are duplicated, one of the most important decisions to be made is the graphic representation on the disc itself. One of the first things people will notice is the artwork on the disc. In order to create the greatest impact, careful thought needs to be given to not only ‘what’ goes on the disc, but also ‘how’ it is done. The primary options are printed disc labels or on disc printing. There are certain factors to consider when deciding which method to employ for your media project.

1. Quality control – With printed disc labels, many issues arise that may negatively impact your final product that are not present with on disc printing. Such problems as centering images, controlling the print bleed parameters, and bubbling between the label and the disc surface, can ruin an otherwise superior disc. With on disc printing, all of these factors are mitigated and the end result is a disc that is visually engaging and at the highest standard.

2. Playability- On projects with printed disc labels, there is the distinct possibility of producing a wrinkled or off-center label. When one of these discs spins at high speeds, it could quite easily wobble causing playback issues, even causing your system to lock up. With on disc printing, the graphic images are placed directly on the surface, so playability is never an issue.

3. Aesthetics- The aesthetic options for disc labels are the same as for any other paper printing project. There are matte, semi-gloss and gloss stocks available. The options are much greater with on disc printing. With current technology you can choose to print single color, grayscale, or full color text and images with color thermal, digital UV, offset, silkscreen or black text printing in all different grades from matte to high gloss.

When deciding on the printing options for your media project, all three of these factors must be considered. If you want to stand apart from the competition, take the time to learn about your options. Consult with your duplication and replication facility to ensure your choices will provide the optimal finished product.

Find us on